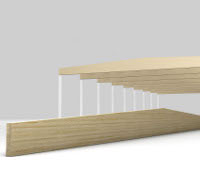

Cross Laminated Timber / X-LAM

High material quality combined in one product: X-LAM as a solid cross laminated panel can easily substitute brick, block, concrete and timber frame systems. The areas of application are:

Large solid panels form walls, roofs, floors and even lift shafts and stairs. They can be used as bracing and load bearing elements internally and externally (protected against weather) in residential, community and industrial buildings.

Large solid panels form walls, roofs, floors and even lift shafts and stairs. They can be used as bracing and load bearing elements internally and externally (protected against weather) in residential, community and industrial buildings.

X-LAM panels have three, five, seven or more uneven layers right-angled stacked on each other in which the surface area of the panels is glued together in a press. The advantages for architects and designers are obvious. Due to its layer structure individual top layers could be used if needed and an excellent structural performance can be achieved, even with a high acoustic and thermal characteristics. Except the maximum size restrictions there is no grid to be considered. It is easy to realise constructional systems with small components height and a low dead load. This means to achieve high flexibility at the least possible costs.

The timber comes from sustainable forestry in Europe. Compared to other solid building systems the using of primary energy for the production of X-LAM is very low. This is why the use of X-LAM timber panels helps to reduce CO2-emissions considerably and thus decreases the greenhouse effect for future generations.

Engineered Beams

Laminated Timber in straight shapes is widely used as a structural material for rafters and roof racks with a span length of 50 m, curved structural members can span distances up to 150 m. The lightweight-product Laminated Timber is the building material of choice for extensive span lengths.

Many arch forms are possible because the trusses can be adjusted to the slope easily and twisted structural members can be used for sophisticated formwork. Laminated Timber as a structural product is often used where the structure of a building is exposed as an architectural feature.

Many arch forms are possible because the trusses can be adjusted to the slope easily and twisted structural members can be used for sophisticated formwork. Laminated Timber as a structural product is often used where the structure of a building is exposed as an architectural feature.

The smooth surface avoids defective deposits and the resistance to chemical aggressive climates enhances the range of application of the product, too. The use of pre-fabricated structural members of timber guarantees a fast construction period. Supporting structures of Glulam can be installed with all common roof-covering systems and are also easily connected with existing buildings or crafts.

Arched Beams

Fish-Bellied Beams

Pitched-Cambered Beams

Three Pinned Hinged Frames

Continuous Beams

Arched or curved glulam beams are often used where the structure of a building is exposed as an architectural feature. With regard to cost-effectiveness, self-weight and aesthetic attractiveness, other structural components are far less suited where these criteria are demanded. Curved glulam structures allow lightweight buildings as a result of slender and simple structures and shapes.

Arched or curved glulam beams are often used where the structure of a building is exposed as an architectural feature. With regard to cost-effectiveness, self-weight and aesthetic attractiveness, other structural components are far less suited where these criteria are demanded. Curved glulam structures allow lightweight buildings as a result of slender and simple structures and shapes.

The bottom profile of these structural members has the form of a parabola and this reflects the ideal moment distribution of the beam. As a result, the stress / strain characteristics of fish bellied beams are excellent. Due to their harmonious and aesthetic shape, fish bellied beams are often used when the structure of a building is exposed as an architectural feature. In situations like that of a single nave hall, the roof will be built as a single-pitch roof. If the hall has two or more naves with central support, a gabled roof will be realised. Fish-bellied beams can be used as ceiling joists, floor joists and as binding beams.

The bottom profile of these structural members has the form of a parabola and this reflects the ideal moment distribution of the beam. As a result, the stress / strain characteristics of fish bellied beams are excellent. Due to their harmonious and aesthetic shape, fish bellied beams are often used when the structure of a building is exposed as an architectural feature. In situations like that of a single nave hall, the roof will be built as a single-pitch roof. If the hall has two or more naves with central support, a gabled roof will be realised. Fish-bellied beams can be used as ceiling joists, floor joists and as binding beams.

Straight Bottom Flange

Straight Bottom Flange

Hoisted Bottom Flange

Although this kind of beam offers the same advantages as the pitched cambered beam. A further advantage of pitched cambered beams with hoisted bottom flange is that the roof pitch can be increased up to 20°. These beams could be specified where a concrete / clay tile covering is demanded. However, with the increase in roof pitch, the tensional strength shall also be increased and therefore it shall be necessary to apply threaded bolts or planking to the connection design. It is advisable to mention this procedure in the project specification.

Three pinned hinged frames are a very efficient form of structural design as a result of effective load transmission to ground. Given this efficiency the glulam material consumption can be kept to a minimum. Further, three pinned hinged frames are a very cost-effective solution because the building foundations can be realised at optimal cost.

Three pinned hinged frames are a very efficient form of structural design as a result of effective load transmission to ground. Given this efficiency the glulam material consumption can be kept to a minimum. Further, three pinned hinged frames are a very cost-effective solution because the building foundations can be realised at optimal cost.

All in all, the use of three pinned hinged frames is only restricted by transport limitations and the challenge to realise a lightly loaded supporting structure.Three pinned hinged frames are commonly used to free-span equestrian halls, recreational buildings, sports halls, industrial halls and agricultural buildings.

Continuous beams are an effective and economic solution for large span structures that may be applicable in large production halls or warehouses. For this construction continuous beams are used as the principal load-bearing elements in order to cover large parallel sections of roof. As the moment distribution of continuous beams is excellent, the bending under load and the stress concentration can be optimised. In the case of extremely large spans, joints in the glulam are factory engineered and executed on site in order to facilitate the transport of the individual structural members.

In order to ensure adequate drainage falls over the roof areas, a roof-pitch of between 2 – 5° is recommended. Depending on the application area, the internal columns to sub-divide the space and the principal external columns can be executed in different materials (e.g. fixed ended reinforced concrete internal columns whilst pin-ended timber columns are used around the building perimeter).

Standard Beams

Thanks to our express line unit straight structural members of glulam are available on short notice. The just in time production process makes sure, that the material is cut accurately to the millimetre according to our customer's requirements.

Without limitations on standardized sizes, cross-sections in between 6 to 30 cm width, 10 to 100cm height and 2.5 to 18m length are available. But also shorter lengths or CNC-machined beams directly ready for assembly or on consignment are possible on customers request.

Without limitations on standardized sizes, cross-sections in between 6 to 30 cm width, 10 to 100cm height and 2.5 to 18m length are available. But also shorter lengths or CNC-machined beams directly ready for assembly or on consignment are possible on customers request.

Laminated Timber Panels

Glulam ceiling elements with double tongue and groove laminated timber panels are massive and extensive structural members of glued boards fitted in a parallel and upright position. They are used as supporting or not-supporting exterior- and interior walls, and for ceilings and roofs.

Your advantages when using laminated timber panels:

Your advantages when using laminated timber panels:

- Comfortable indoor climate thanks to the moisture regulating material properties of timber

- Excellent heat- and fire resistance performance is possible even without paint finish or additional provisions

- As a light weight product laminated timber panels are especially cost-effective with regard to transport and assembly

- Laminated timber panels can be applied in directly visible areas without additional smoothing or plastering work

- Due to the limited height of the structural components, laminated timber panels have a high transport volume

- Loadable right after construction

- Finishing work can be realised immediately

- Subsequent wall openings or recesses are no problem

- High degree of pre-fabrication: The processing is effected in the production plant regardless of the weather conditions, short construction period

- Each floor plan and each kind of building design can be realised

- Laminated timber panels are the ideal building material for traditional solid constructions, timber frame constructions and timber skeleton constructions

Round Columns

Round columns cannot only be used as an architectural eye-catcher, they also offer many advantages:

- Polished surface

- Selected timber quality

- Cost-efficient thanks to most modern production

- Short delivery times

- It’s possible to produce conical forms

- Stress grade GL 24h/c (BS 11) (higher stress grades possible upon request)

Timber-concrete Composite Constructions

Timber-concrete composite constructions are innovative, because the benefits of a reinforced concrete ceiling and the benefits of a timber ceiling system complement each other so well.

Thanks to the excellent synergy of timber and concrete it’s possible to realise design versions for ceiling-, wall- and bridge-systems which are both, economical and sophisticated in terms of structural engineering.

Thanks to the excellent synergy of timber and concrete it’s possible to realise design versions for ceiling-, wall- and bridge-systems which are both, economical and sophisticated in terms of structural engineering.